في X-RHEA Packing، لا يحدث الجودة بالصدفة. بل يتم بناؤها خطوة بخطوة، داخليًا، من خلال عملية إنتاج منسقة بشكل وثيق، والتي كسبت ثقة العلامات التجارية الراقية في جميع أنحاء العالم. الآن، بينما تنظر الشركة نحو عام 2026، فإن هذه الأسس نفسها تمثل طريقاً نحو تحول مدروس نحو الت manufacturing الذكي—دون فقدان اللمسة البشرية التي تميّز عملها.

🔹 مصمم ليدوم: سير عمل فعّال

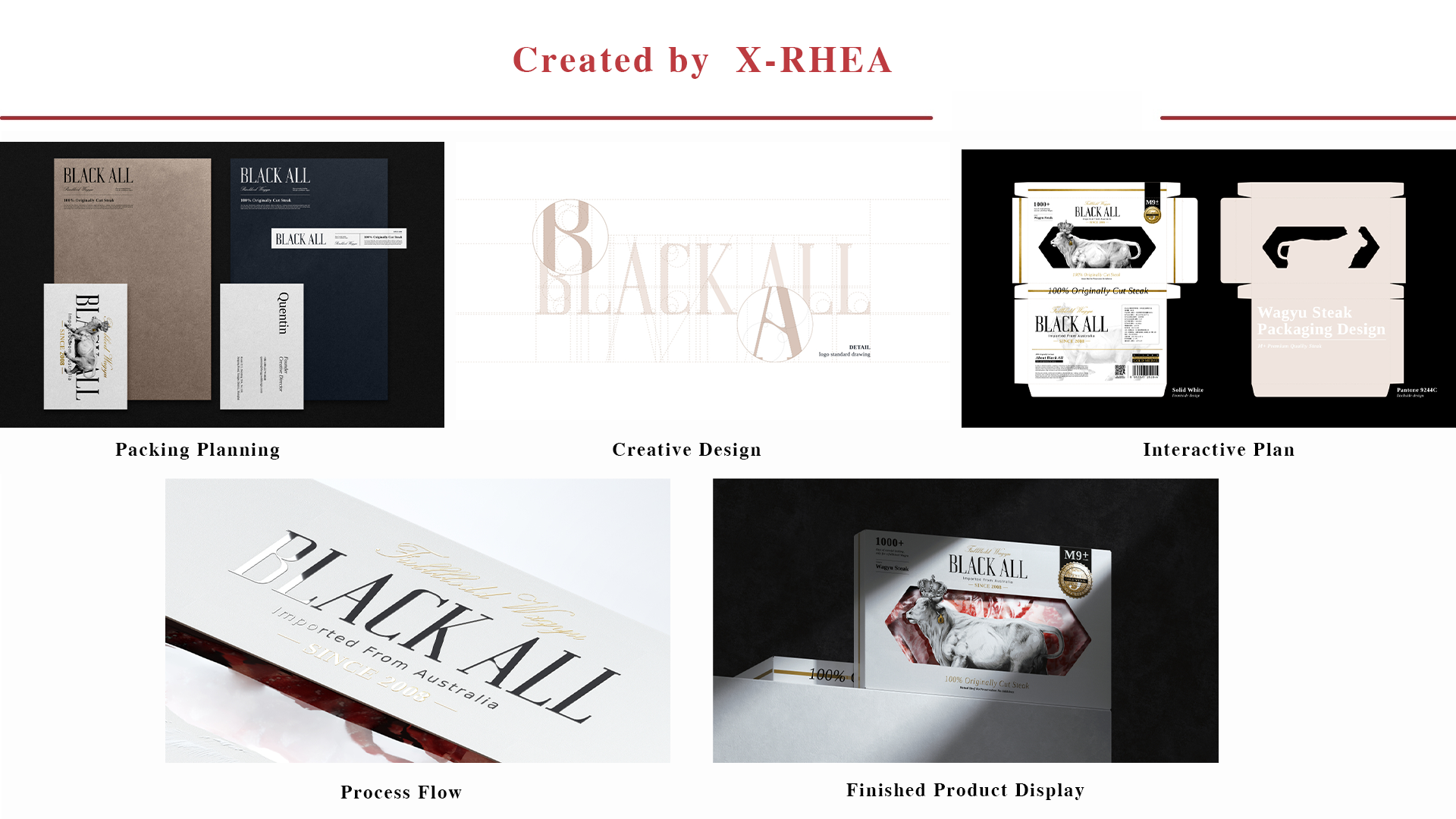

يبدأ كل مشروع في X-RHEA بالتخطيط للتعبوية. في هذه المرحلة، تستعرض الفرق القصة الخاصة بالعلامة التجارية، واحتياجات المنتج، والموقع في السوق لاختيار الهيكل والمواد والتفاصيل الوظيفية المناسبة. تضمن هذه الوضوح المبدئي سير العملية بأكملها بانسيابية—بدون افتراضات، وبدون مفاجآت في اللحظة الأخيرة.

🎨 حيث يلتقي التصميم بالواقع

تلي هذه المرحلة التصميم الإبداعي—ليس فقط من حيث الشكل البصري، بل تعبوية فعّالة في العالم الواقعي. يعمل المصممون عن كثب مع الخبراء في الإنتاج منذ اليوم الأول، لضمان تنفيذ كل انحناء وطي وتشطيب بدقة على أرض الواقع.

بالنسبة لفئة مختارة من العملاء الرئيسيين — خاصة في مجالات النبيذ والأطعمة الفاخرة والسلع الراقية — يقوم الفريق أيضًا بإضافة عناصر تفاعلية في المراحل المبكرة: مثل ميزات مكافحة التزييف، وتقنيات التتبع، أو دمج عبوات ذكية تُبرز المنتجات عن المنافسين على الأرفف وفي المتاجر الإلكترونية.

🔄 انتقالات سلسة، وأخطاء أقل

بمجرد إقرار التصاميم، يبدأ الإنتاج فورًا. وتتم عمليات الطباعة والطلاء والتجميع والتفتيش جميعها ضمن سقف واحد. وبما أن كل قسم يتحدث اللغة نفسها ويشترك في نفس الأهداف، تظل الاتصالات متماسكة، والجداول الزمنية واقعية، وجودة المنتج مستقرة.

✅ الفحص النهائي: هل يتطابق مع الرؤية؟

قبل شحن أي منتج، تمر القطع النهائية بمراجعة نهائية بناءً على رؤية التصميم الأصلية، والمواصفات الهيكلية، ومعايير الجودة. ولا يتعلق هذا الأمر فقط باكتشاف العيوب، بل بالحفاظ على رؤية العلامة التجارية حتى أدق التفاصيل.

🚀 أكثر ذكاءً، وليس أسرع: خارطة طريق 2026

لا تتسرع X-RHEA في التوجه نحو الأتمتة لمجرد الأتمتة. ابتداءً من عام 2026، ستبدأ الشركة في دمج أدوات رقمية تعزز — وليست تستبدل — سير العمل الحالي. مثل:

• تتبع الإنتاج في الوقت الفعلي

• إمكانية التتبع الشامل من ملف التصميم إلى التسليم

• تنسيق أكثر ذكاءً بين القرارات الإبداعية وقدرات التصنيع

الهدف؟ دقة أكبر، واتصال أوضح، ومساحة أوسع للتخصص المعقد، كل ذلك مع الحفاظ على الحرفية في المركز.

🔮 لماذا يهم هذا

في سوق تتطلب فيه العلامات التجارية الرائدة كل من الت uniqueness والموثوقية، فإن مزيج X-RHEA من عملية منضبطة وتقنية استشراف المستقبل يقدّم شيئًا نادرًا: تميّز قابل للتوسعة ويظل يحمل طابع شخصي. ومع تضبِع الخط الفاصل بين التعبئة المادية والرقمية، فإن هذا التوازن سيصبح أكثر قيمة باستمرار.

بالنسبة للعلامات التجارية التي تهتم بكيفية صنع عبواتها — وليس فقط بمظهرها — فإن X-RHEA تبني المستقبل، sigar علبة واحدة بعناية في كل مرة.